Water ring vacuum pump cavitation principle and the method of prevention

| 1, cavitation generation principle

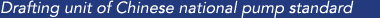

Water ring vacuum pumps in operation, if its flow components (usually somewhere in the impeller blade inlet later) when the pumping pressure of the liquid is increased relative to the later liquid vapor pressure under heat, the liquid will be in the end where the gasification generating a large number of steam bubbles constitute, when the liquid contains a large number of bubbles by a low pressure area forward of the impeller, a low pressure liquid bubble around so abruptly cause an enlarged bubble burst. In the bubble burst simultaneous condensation, liquid particles filling a hole at a high pace, at this moment to generate very strong water hammer and strikes at high efficiency in combating non-metallic name of strikes, how much stress to reach the most number of one thousand one hundred atm, strikes efficiency reached tens of thousands of times per second, will be significant when the thickness breakdown – this is the water ring vacuum pump cavitation. (What is the principle of water pump cavitation? Cavitation is caused by the liquid gasification, liquid molecules escaping liquid nominal, into the inner gas molecule, known as “gasification.” Size of the gasification of liquid level and pressure , heat up and down has nothing to do. dissolved in the liquid gas, at a pressure and temperature changes will be released into the form cavitation. When the liquid external pressure rises, lower than the saturation vapor pressure of the liquid at the time of the heat, in all waters constitute air bubbles or pockets; and in the center of the bubble pressure rise suddenly crushed by the pressure around the liquid flow due to high elasticity progress to the bubble core extrusion, causing hydraulic strikes on facilities such microbubble generation, collapse. crack and overcurrent produce physical and chemical effects on behalf of the entire inner called cavitation when cavitation bubbles generated when fixed to a lower pressure, its volume decreases resulting in disillusionment. This because of the pressure rise in the liquid bubble disappearance scene called cavitation collapse.) Water ring pump cavitation damage and cavitation damage to the principle of centrifugal pump is the same, pitting phenomenon is occurring in the bubble generation and split parts, metal surface, there will be severe cellular damage. If the pump impeller cavitation site has large residual pressure will cause impeller cracking.

2, cavitation hazards

Water ring vacuum pump cavitation corrosion is generated in the bubble and broken parts, non-metallic nominal emerged pitting phenomenon, it will emerge a major cellular destruction. Pump impeller cavitation site has large residual stress, can lead to stress released, cracks. Because the pump cavitation bubbles in the low pressure area have produced a sudden burst, and along with the strong water hammer generated noise and vibration can be heard crackling like popcorn-like tone. Then the above-mentioned bubble burst in nominally non-metallic, non-metallic nominal will be another strong water hammer emerged pitting, non-metallic grain loose and peeling from a honeycomb and even perforation. Cavitation destroyed except for the mechanical action, also accompanied by a variety of simple role electrolysis, chemical erosion. Destroy motivation theory indicate that the central pump flow element cavitation destruction of the site, is the bubble disappearance. Vacuum pumps need to use a liquid medium as a job. Each liquid at a certain temperature has a corresponding saturation vapor pressure. When the relative pressure of the suction on the verge of the sea, the more saturated vapor pressure of the liquid, the liquid state on the verge of evaporation. Then, in the name of the job was sucked waters will produce a large number of bubbles in the job because the liquid fluid vapor can produce dragon Huju jobs cavity space of all jobs cavity pump suction external power will rise. When the suction pressure of the waters reached the saturation vapor pressure of the job he was able to find a job was a job full of heavily cavity steam pump at the brink of the external suction power to zero, at which point the pump cavitation phenomenon is also the most important. 3.Elimination method and prevention Water ring vacuum pumps work long hours under cavitation state, it will cause the pump noise, vibration becomes large, and even cause damage to the pump, and thus should try to prevent water ring vacuum pump in the cavitation mode of operation, can pass seq steps:

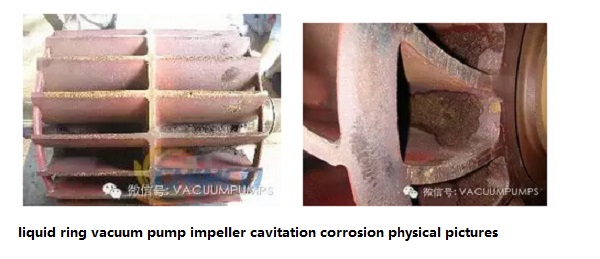

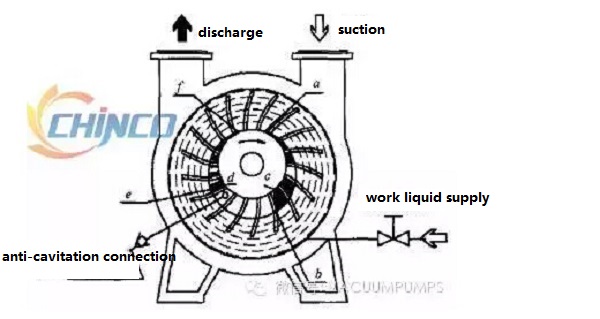

(3) Installation of gas pipeline corrosion protection Cavitation protection tube fitted with a vacuum pump, cavitation bubbles produced during the compression process is broken when introducing higher pressure non-condensable gases from the outside can replenish space because the bubble burst occurs, this can reduce the large pump cavitation hazards and reduce noise and vibration caused by cavitation. Means there is a vacuum pump cavitation cover tube, inside the cavitation bubbles generated during compression within the rupture, the introduction of higher pressure from the non-condensable gases can replenish internal bubble burst and because of the emergence of space, so can greatly increase cavitation of pump cavitation cause harm and increase

(4) with an air ejector Air ejector effect is the use of absolute atmospheric pressure in the vacuum pump to generate air jets, lose less than the pump suction pressure within the injector thus eliminate the vacuum pump ultimate pressure, prevent pump cavitation, played the role of a vacuum pump cover . Because the atmosphere is to prevent the ejector pump cavitation, pump cover and set properly provided with an air ejector vacuum pump, vacuum suction constituted better than not fitted .

(5) selection of a liquid with a lower vapor pressure as the working fluid.

High quality liquid ring pump, compressor manufacturers! Industrial products OEM manufacturers! |