Application and characteristics

The liquid ring vacuum pumps and compressors of 2BE series are high-efficient and energy-saving products developed by our company on the basis of our scientific achievements and production experiences over the years combining with the advanced international technique of similar products. They are usually used to suction the gas without solid particle, undissolved and noncorrosive gas in order to form vacuum and pressure in the closed container. By changing the structure material, they can also be used to suction corrosive gas or use corrosive liquid as operating liquid. They are widely used in paper-making, chemical, petrification, light industry, pharmacy, instruments, metallurgy, construction, electronical appliance, coal-cleaning, mineral concentration, fertilizer, etc.

These single-stage and single-acting pumps are simple in structure, convenient in maintaining, reliable in operating, efficient and energy-saving. They can run under tough working conditions with large drainage discharge and changing load impact. 2BE vacuum pumps adopt unique polytetrafluoroethylene valve plates (former liquid ring pumps use ball valves) for their exhaust systems. Each valve plate is covered on vents in outer side of a port plate and fixed by a stainless steel baffle at its other side. Curvature of the valve plate changes with inlet pressure so that pumping medium can be discharged when it reaches the inlet pressure. Such structure avoids over-compression in a vacuum system and automatically adjusts exhausting area to lower power consumption, thus a best operating efficiency can be obtained.

We have optimized designs of key parts like distribution plate, impeller and pump shaft by simplifying their structures and improving their performances, thus energy-saving target has been reached. Dynamic balance problem is radically solved because during impeller welding, blades are formed by one-step stamping with rational molded lines and all wheel hubs are processed. The impeller and pump shaft combined by shrinkage interference fit perform reliably and smoothly. Blades of the impeller will obtain good ductility after the impeller is welded and processed by overall heat treatment, thus impact resistance and flexure resistance of the blades are fundamentally guaranteed for application under tough working condition with changing load impact. The 2BE pumps are convenient in assembly, application and maintenance and simple in operation due to their gas-water separators, several vents at different positions, vent valve manholes in pump covers and clearances between the distribution plates and impellers which are adjusted by glands at both ends of locating shafts.

All vacuum pumps will be subjected to strict inspections and tests in our testing center so as to guarantee their excellent, reliable and long lasting performances.

Application

Tail gas/flare-gas recycle .recycle of VCM in PVC device .recycle gas compression .polyester production .liquid chlorine production

Pressure swing adsorption (PSA).vacuum crystallization and filtration .tower top vacuum system for reduced pressure distillation of crude oil

Compression of inflammable and explosive gases like ethyne and hydrogen .compression of toxic and corrosive gases like chlorine .vacuum transfer of various materials

Water ring vacuum pump: model expression method

Models of 2BE pumps are expressed by 8 words (letters) and numbers as follows:

2BE1– <1><2> <3>-<4>

2BE1is the name of single-stage water ring vacuum pump and 1 stands for 2BE high vacuum series.

<1><2> stands for nominal radius (cm) of the impeller.

<3> stands for code of width-diameter ratio of the impeller, specifically, 1 stands for B(width)/D(diameter)=0.5; 2 stands for B/D=0.75, 3 stands for B/D=1 and 5 stands for B/D=1.2.

<4> stands for code of minimal suction pressure, specifically, 0 stands for limiting vacuum of 33hpa and 1 stands for limiting vacuum of160hpa.

For example, “2BE1-403-0” stands for a single-stage water ring vacuum pump in which the nominal diameter of the impeller is 800mm, width-diameter ratio is 1 and minimal absolute suction pressure can reach 33hPa. Such pump can also be recorded as 2BE1-403 (since limiting vacuum of 2BE1 series is 33hpa and limiting vacuum of 2BE3 series is 160hpa, the <4> is usually ignored).

Table of performance of 2BE1 liquid ring vacuum pumps (performance curves of compressors attached)

Click to activate the links of large figures for the performance curves. Please wait for a while if the figures appear slowly.

| 型号

Model |

转速 (传动方式) Rotating speed(Rotating mode)r/min

|

轴功率 Shaft powerkW |

配用电机

Motor |

极限真空度

(表压) Limiting vacuum (Gage pressure) hpa |

最大抽气速率

Maximum suction rate |

泵头重

Pump head weight |

|

| m3/h | m3/min | ||||||

| 2BE1-102 真空泵曲线Vacuum pump curve |

1450(D) 1750(V-belt) |

6.0 8.0 |

Y132M-4-7.5 Y160M-4-11 |

33hpa (-0.097MPa) |

246 290 |

4.1 4.8 |

110 |

| 2BE1-103 真空泵曲线Vacuum pump curve |

1450(D) 1750(V-belt) |

8.2 11.1 |

Y160M-4-11 Y160L-4-15 |

33hpa (-0.097MPa) |

340 412 |

5.7 6.9 |

125 |

| 2BE1-152 真空泵曲线Vacuum pump curve |

1450(D) 1625(V-belt) 1750(V-belt) |

12.5 15.0 17.2 |

Y160L-4-15 Y180M-4-18.5 Y180L-4-22 |

33hpa (-0.097MPa) |

450 510 535 |

7.5 8.5 8.9 |

175 |

| 2BE1-153 真空泵曲线Vacuum pump curve Attached:101-153 Compressor curve |

1450(D) 1100(V-belt) 1300(V-belt) 1620(V-belt) 1750(V-belt) |

16.3 10.613.4 19.6 22.3 |

Y180M-4-18.5 Y160L-4-15Y180M-4-18.5 Y180L-4-22 Y200L-4-30 |

33hpa (-0.097MPa) |

600 445535 648 700 |

10.0 7.48.9 10.8 11.7 |

200 |

| 2BE1-202 真空泵曲线Vacuum pump curve Attached: Compressor curve |

980(D) 790(V-belt) 880(V-belt) 1100(V-belt) 1170(V-belt) 1300(V-belt) |

18.2 13.4 16.3 23.8 25.7 30 |

Y200L2-6-22 Y180M-4-18.5 Y180M-4-18.5 Y200L-4-30 Y200L-4-30 Y225S-4-37 |

33hpa (-0.097MPa) |

750 590 670 860 888 950 |

12.5 9.8 11.2 14.3 14.8 15.8 |

460 |

| 2BE1-203 真空泵曲线Vacuum pump curve Attached: Compressor curve |

980(D) 790(V-belt) 880(V-belt) 1100(V-belt) 1170(V-belt) 1300(V-belt) |

29.5 21.2 24.8 33 38 42 |

Y250M-6-37 Y200L-4-30 Y200L-4-30 Y225M-4-45 Y225M-4-45 Y250M-4-55 |

33hpa (-0.097MPa) |

1080 870 980 1210 1320 1390 |

18 14.5 16.3 20.2 22.0 23.2 |

530 |

| 2BE1-252 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

740(D) 565(V-belt) 660(V-belt) 830(V-belt) 885(V-belt) 938(V-belt) |

38 23.7 31.8 4554 60 |

Y280M-8-45 Y200L-4-30 Y225S-4-37 Y250M-4-55 Y280S-4-75 Y280S-4-75 |

33hpa (-0.097MPa) |

1700 1200 1500 1770 2000 2100 |

28.3 20.0 25.0 29.5 33.3 35.0 |

880 |

| 2BE1-253 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

740(D) 565(V-belt) 660(V-belt) 740(V-belt) 792(V-belt) 820(V-belt) 880(V-belt) 940(V-belt) |

54 37.2 45 50.8 60 68 75.1 88 |

Y315M-8-75 Y225M-4-45 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-75 Y280M-4-90 Y315S-4-110 |

33hpa (-0.097MPa) |

2450 1690 2100 2340 2560 2640 2780 3050 |

40.8 28.2 35 39 42.7 44 46.3 50.8 |

930 |

| r>2BE1-303 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

740(D) 590(D) 466(V-belt) 530(V-belt) 583(V-belt) 660(V-belt) 740(V-belt) |

98 65.5 48 58 64 79.8 100 |

Y315L2-8-110 Y315L2-10-75 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 |

33hpa (-0.097MPa) |

4000 3200 2520 2820 3100 3550 3840 |

66.7 53.3 42 47 51.7 59.2 64 |

1700 |

| 2BE1-305 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

740(D) 590(D) 490(V-belt) 530(V-belt) 583(V-belt) 660(V-belt) 740(V-belt) |

108 70 55 61 68 90 110 |

Y355M1-8-132 Y355M1-10-90 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-132 |

33hpa (-0.097MPa) |

4520 3750 3150 3380 3700 4090 4550 |

75.3 62.5 52.5 56.4 61.2 68.1 75.8 |

1820 |

| 2BE1-353 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

590(D) 390(V-belt) 415(V-belt) 460(V-belt) 530(V-belt) 580(V-belt) 620(V-belt) 660(V-belt) |

121 63 697995 115 133 |

Y355L2-10-160 Y280S-4-75 Y280M-4-90 Y280M-4-90 Y315S-4-110Y315M-4-132Y315L1-4-160 Y315L2-4-185 |

33hpa (-0.097MPa) |

5300 3580 3700 4100 4620 51605500 5850 |

88.3 59.7 61.7 68.3 77.0 8691.7 97.5 |

2300 |

| 2BE1-355 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

590(D) 390(V-belt) 420(V-belt) 460(V-belt) 523(V-belt) 590(V-belt) 660(V-belt) |

136 75 80.890 113 136 182 |

Y355L2-10-160 Y280M-4-90 Y280M-4-90 Y315S-4-110 Y315M-4-132 Y315L1-4-160 Y315L2-4-200 |

33hpa (-0.097MPa) |

5700

4180 4850 |

95 69.7 71 80.8 87.1 100 108 |

2450 |

| 2BE1-403 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

330(V-belt) 372(V-belt) 420(V-belt) 472(V-belt) 530(V-belt) |

98 110 131 160 213 |

Y315M-4-132 Y315M-4-132 Y315L1-4-160 Y315L2-4-200 Y355M2-4-250 |

33hpa (-0.097MPa) |

4860 5400 6470 7380 8100 |

81 90 107.8 123.0 135.0 |

3750 |

| 2BE1-405 真空泵曲线Vacuum pump curve附:压缩机曲线 Attached: Compressor curve |

330(V-belt) 372(V-belt) 420(V-belt) 472(V-belt) 530(V-belt) |

100 118 140 170 216 |

Y315M-4-132 Y315L1-4-160 Y315L2-4-185 Y315L2-4-200 Y355M2-4-250 |

33hpa (-0.097MPa) |

6000 6700 7500 8350 9450 |

100.0 111.7 125.0 139.2 157.5 |

3900 |

Note:

The limiting vacuum of the 2BE1 series is 33hpa (=-735mmhg=-0.097Mpa=33mbar). 1hpa=1mbar,1mmhg=133.3 Pa.

The suction capacity in the table is the maximum capacity. Actual exhaust speed changes as the suction pressure. Specific operating pressure and the performance curves shall be considered when selecting pumps.

Motor power of the vacuum pumps above are appropriate in most cases, but shall be increased accordingly when vent pressures (gage pressure 0.04-0.12MPa) are relatively higher so as to suit to the function as liquid ring compressors. The table also includes performance curves of the pumps when they function as compressors. Pumps can be selected according to the curves in case of such situation.

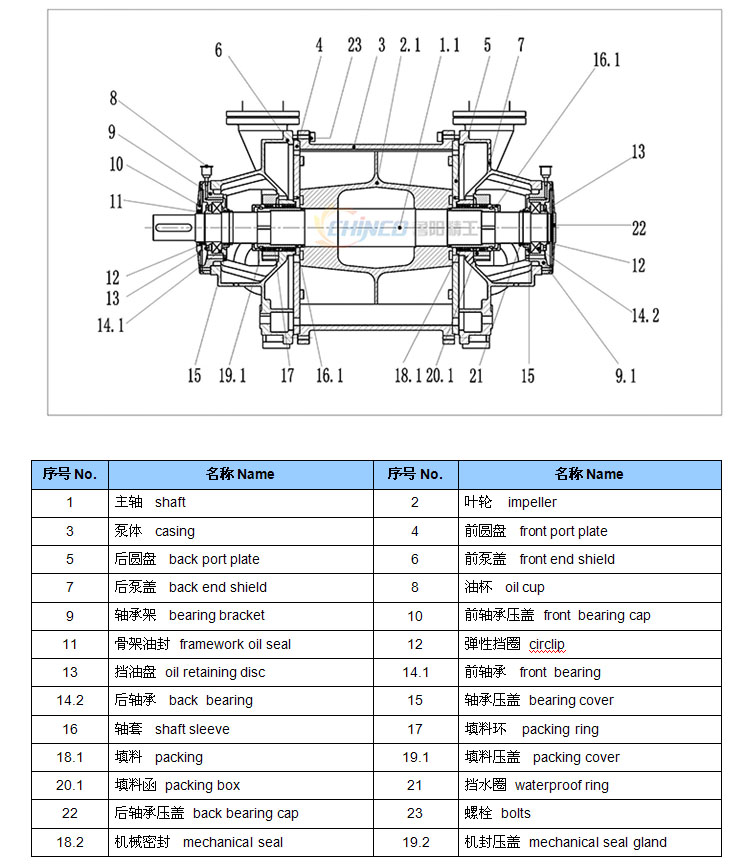

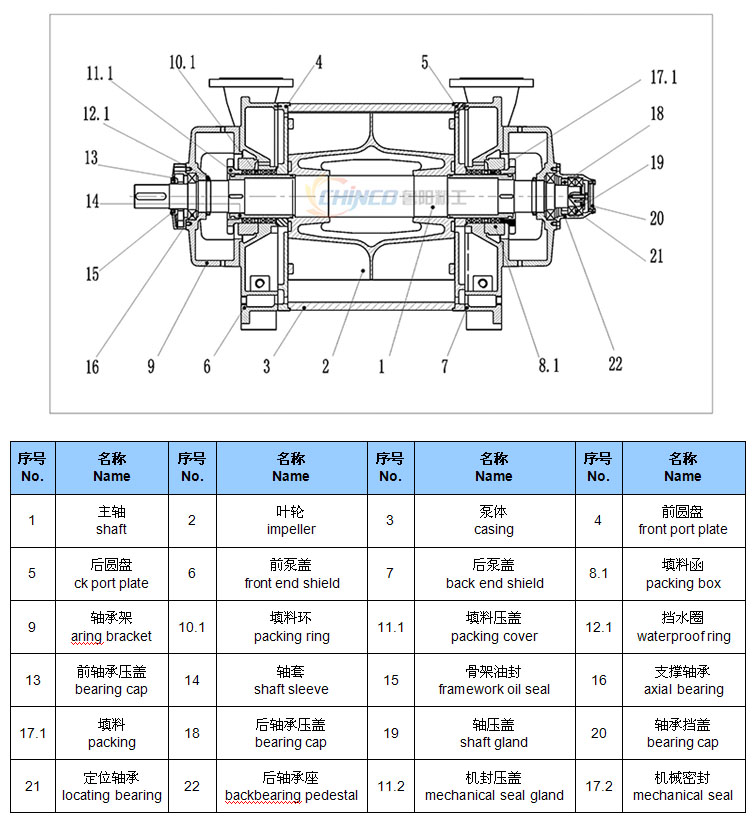

Configuration (102~253)